Drip Distribution

A slightly more complex septic system and one of the most expensive types to date are drip distribution systems. The core technology are based on a special micro-dosing emitter tubing.

Overview

Drip distribution is a technology that utilizes pressurization, filters, timed-dosing and micro-dosing. This works in similar fashion to a sprinkler system, although its discharge is under the ground through small emitters.

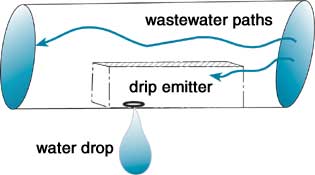

Emitter Technology

Drip Tubing

The drip distribution system has flexible tubing that is half an inch in diameter, with built in emitters designed to discharge at a design certain pressure range. When the pump is discharged the wastewater flows to a valve system.

Drip Tubing Installation Pattern

Drip Zones

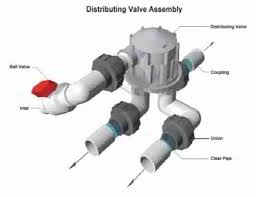

The drip distribution system has a solenoid valve system (with electrically-switch opened valves) directs the wastewater to different areas of the property. These areas are called zones. Each zone is engineered to absorb a portion of the wastewater. Prior to discharge to the designated zone, the wastewater passes through a disk filter.

Drip Disk Filters

Pressure Distribution

Pressure Distribution is not a new concept. It has been used in other states for decades to alleviate the problem of discharging wastewater into clayey soils. The main idea is to evenly distribute the wastewater load evenly over the entire designed soil absorption area. This is done by pumping the wastewater into a pressurized piping system with holes that literally squirt the water evenly into the designed media.

Pressurized septic treatment systems are often difficult to design. They provide a unique and difficult problem in selecting the properly sized and spaced holes in the pressure piping. Pressure piping are composed of sections of Force Main, Manifold, and one or more Laterals. Force main sections transmit the water from the dose tank to the manifold. The manifold splits the force main to the laterals. The laterals are sections of the pressure network that distribute the water to the soil, whether by trench or elevated sand bed.

Some problems with designing these systems are there are meeting the square footage per application hole rule and also meeting the requirement for less than ten percent flow loss, all while maintaining two ft. per second velocity.

Often times these systems require a valve system to ensure these rules are met for dosing every area uniformly.

Distributing valves come in solenoid or non-mechanical flow actuated types.

Timed-Dosing

Timed-Dosing is a newer technology that has been developed which incorporates timers and electical switches to control a pump and activates it at a specific time. This concept helps prevent overloading sensitive soils and a subsequent blow-out or seepage of wastewater from the soil absorption component.

These types of products have rapidly grown in the variety based on advances in sensors and drop in cost of technology.